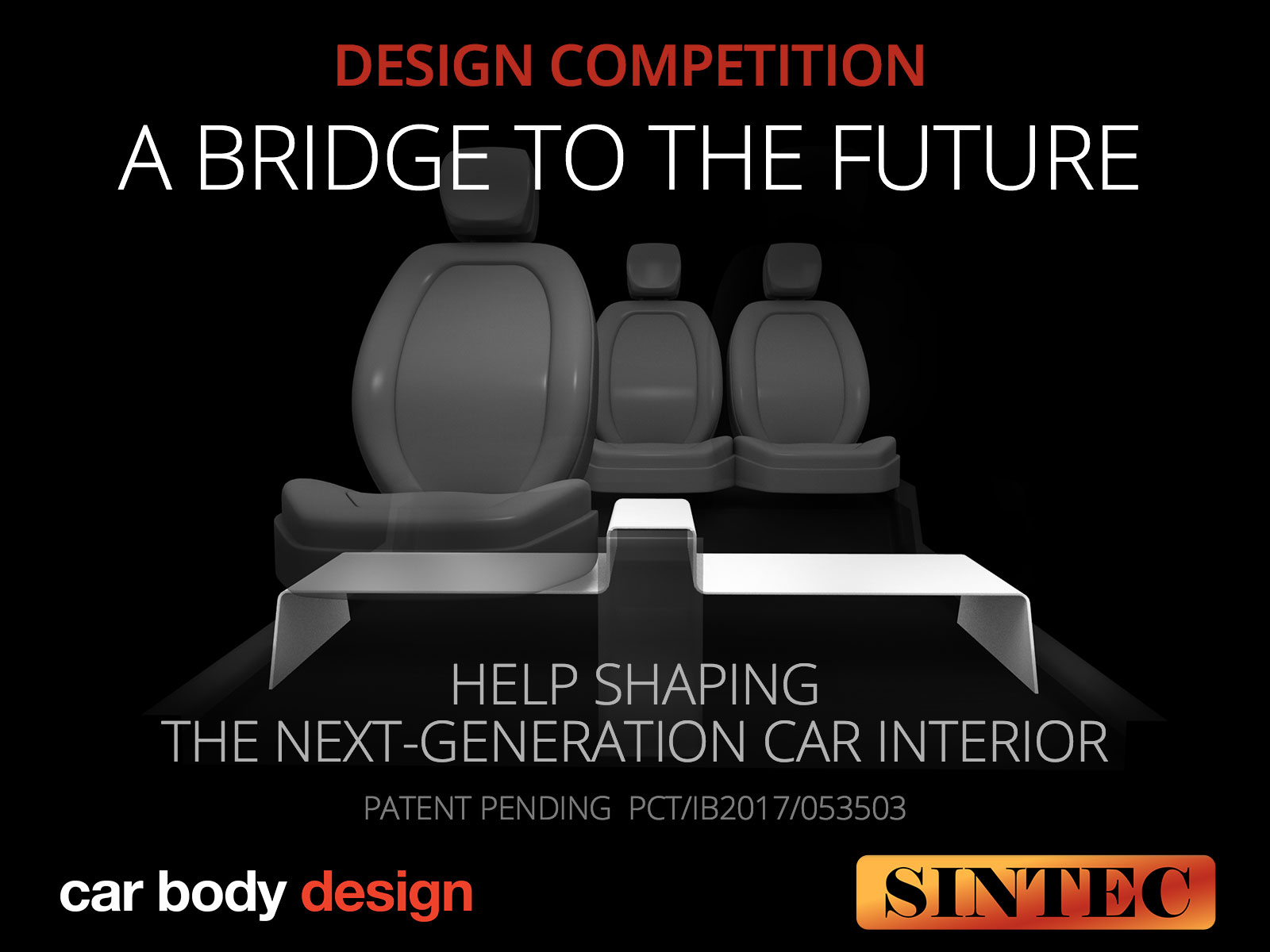

If you are interested in exploring an innovative solution that could revolutionize car seat assembly, this document offers an in-depth analysis. SeatBridge presents a cutting-edge approach to the assembly of front seats, providing significant advantages in terms of production efficiency, passenger comfort, and cost optimization.

Innovation in Production with the DSM Method

The document explains how the Design Structure Matrix (DSM), an analytical process optimization tool, is used to compare the traditional approach with the innovative one proposed by SeatBridge in front seat assembly. Thanks to this methodology, a 30% reduction in assembly time was identified compared to conventional methods, an improvement that can make a difference for car manufacturers.

SeatBridge: More Space, comfort, and Safety for Passengers

One of SeatBridge’s goals is to enhance the passenger experience. The patent allows for a seat configuration that offers more foot space, a modern “living room” aesthetic, and a simpler, easier-to-clean structure. These advantages make SeatBridge an attractive solution for car manufacturers aiming to offer a superior travel experience.

Economic Benefits for Car Manufacturers

Implementing SeatBridge significantly reduces production costs due to the pre-assembly of components and the simplification of the final assembly line. The document highlights that this system can reduce workstations and labor requirements, cutting costs and increasing profitability for car manufacturers.

Ready to Learn More?

To delve deeper into the details of this innovation and its potential impact on the automotive industry, don’t miss the chance to read the full document. You will discover how SeatBridge is paving the way for new possibilities in design, functionality, and commercial benefits.

Read the document and discover a unique vision of the future of the automotive industry!