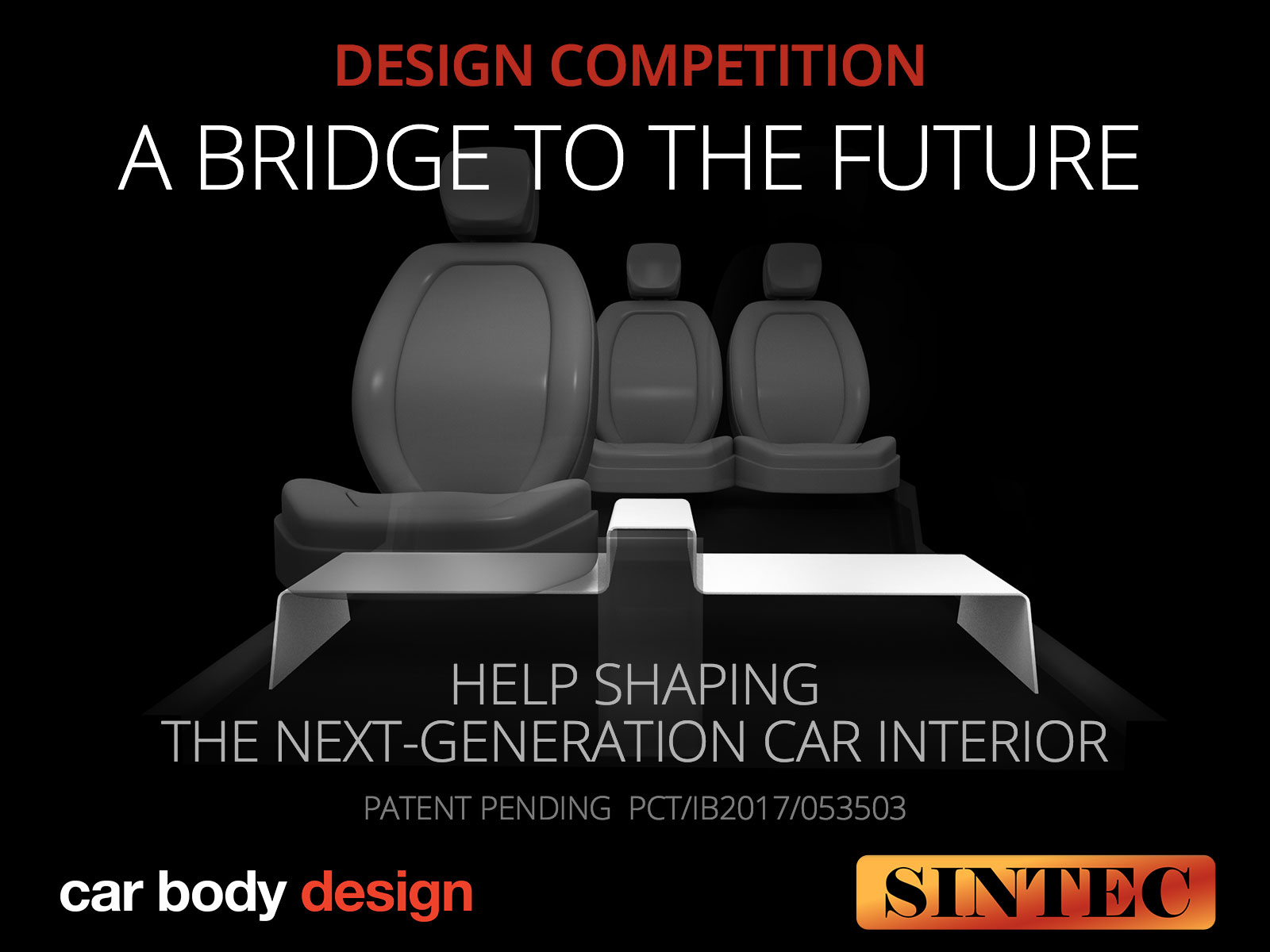

Why SeatBridge Is a Win-Win Solution for Manufacturers

Car production is a meticulous process that balances innovation, efficiency, and cost. The SeatBridge patent disrupts this balance in the best way possible by introducing significant cost savings for both car and seat manufacturers.

The SeatBridge eliminates the need for individual assembly of front seat tracks, dramatically reducing the number of workstations and robots required on production lines. Instead of managing and assembling multiple components, manufacturers receive a fully pre-assembled Front Seats Assembly (FSA). This reduces internal logistics from managing three separate parts to just one, significantly cutting time and manpower requirements.

For seat makers, this innovation increases the turnover-per-car ratio by expanding their role to include the production and delivery of the FSA. Meanwhile, carmakers can reallocate resources saved on assembly to other areas, enhancing overall operational efficiency.

Key benefits for manufacturers:

• Reduced costs on assembly lines and manpower.

• Simplified logistics with a single, integrated unit.

• Enhanced profit margins with fewer resources required.

The SeatBridge not only saves costs but creates opportunities for manufacturers to pioneer a new standard of interior design.

Join us, on 19 February 2025 for an exclusive Automotive Circle Webinar featuring SeatBridge – where revolutionary ideas meet cutting-edge automotive decisions makers. 🚗💡